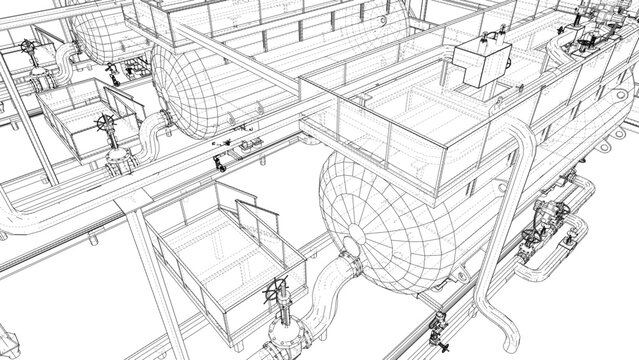

System Planning for Process Systems and Packaging Lines

The planning process is a critical step for both process and packaging line systems. Decades of engineering experience to design the platform for your process and packaging systems.

Our engineers and draftsmen are fully functional using Auto CAD 2D and 3D modeling to create current as-built drawings, demolition plans and proposed equipment layouts. These layouts will be used to shape and complete your final engineered solution. SOLIDWORKS, 3D area scanners and other video technology are available for specific process work.

Equipment Selection

Our engineering and project management team will evaluate your equipment needs, provide recommendations, and include detailed pricing with your project options. When placing equipment orders, lead times are considered in order to avoid delays due to today’s supply chain limitations . Whether it is New or Used Equipment, Robotics, Full System Automation, Standard Technologies, or more Manual Selections, we can assist you in making the best selections for your company.

Implementation of Services

Project execution begins by assigning knowledgeable team members who will begin working immediately to finalize layout designs based on client feedback. Once final designs are locked down, equipment selections are purchased and delivered to site. At this point, McMackin provides customized resource support throughout the implementation process, depending on your project needs.

We generally provide 3 types of technical services

- Complete turnkey approach

- Traditional PM/CM approach

- General Guidance and Support

Get a Custom Quote.

We’d love to learn more about your filling or packaging needs, and help design a custom solution for you.

Did You Know?

Did you know that project success starts with the setting of goals and definition of what success will be? Our team is ready to assist you in reaching your goals and wanted to share a few key points to think about when proceeding with a process or packaging upgrade:

- Communication amongst the project team is key for project implementation efficiency and success. Be prepared to provide information and ask questions.

- Be sure to pick a qualified organization. Our PMP certified and experienced team will work to develop and implement a plan to achieve the project goals. Our dedicated team will supervise, support and guide your project towards success.

- Be prepared to support your equipment after start-up by having a maintenance plan in place and factory suggested parts available.